From a system compliant with the UNI ISO 9001:2015 standards we focus our attention on achieving the objectives, which are fixed defining a proactive culture of improvement, oriented to prevention.

The objective is not only achieving compliances, but also measure the system performance, while reaching results.

We use methodologies like PDCA PLUS; the processes are constantly monitored, measured, analyzed and evaluated and corrective actions are extended for prevention purposes. The traceability is ensured from raw material purchase, up to the finished product supply.

We adhere to IMDS system, common to the entire Automotive supply chain.

The research of always greater collaboration between all the involved company sectors, for the achievement of a common objective, allows us to operate, improving our feedback level on the market, raising the product quality, satisfying and anticipating the customer expectations.

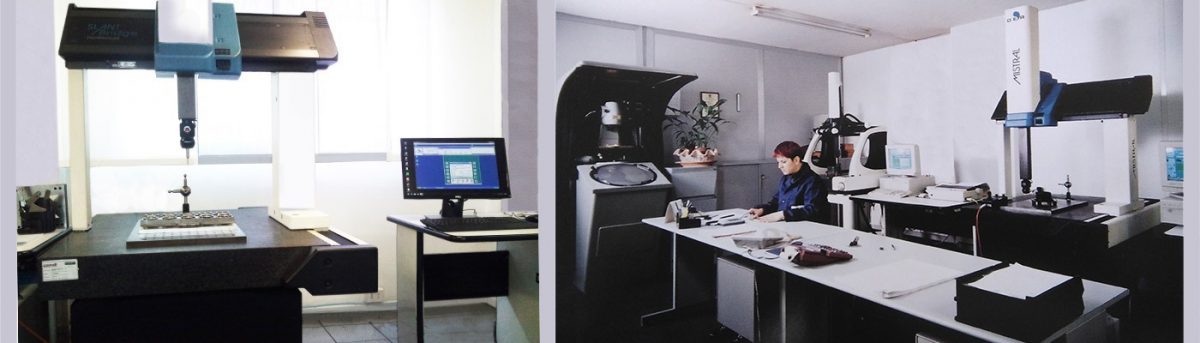

LABORATORY FOR QUALITY CONTROL

The Quality Department operates from material acceptance, through tests and prefixed analysis during all the working phases, up to the final products test.

The metrology room is equipped with 2 three-dimensional coordinate measurement benches, to which the data processing software is associated.

The equipment for functional, static, dynamic and destructive tests are used on materials and products. All the tooling and devices are maintained and inspected according to ISO Q.M. specifications.

All the production units support the laboratory, operating under a self-control regime, using latest generation analogic and digital measurement and control instruments.